It is applicable to dangerous sites which contain methane (commonly known as gas) and coal-dust explosion, capable of handling sewerage which contains a mixture of insoluble solid contents such as sediment, coal slime, cinders, fibrous material, etc. it is also applicable for transporting rain water and sewage containing solid particles at constructions, hospitals, residential areas, municipal projects, roads, factory sewage, etc. Fully range of models, power range is 2.2kw-315kw,flow range is 10m³/h-2500m³/h,head range is 7m-700m,all products are designed with full head, no overload throughout whole head.

Categoria de producto

Category

Working Condition

Model Description

Performance Curve

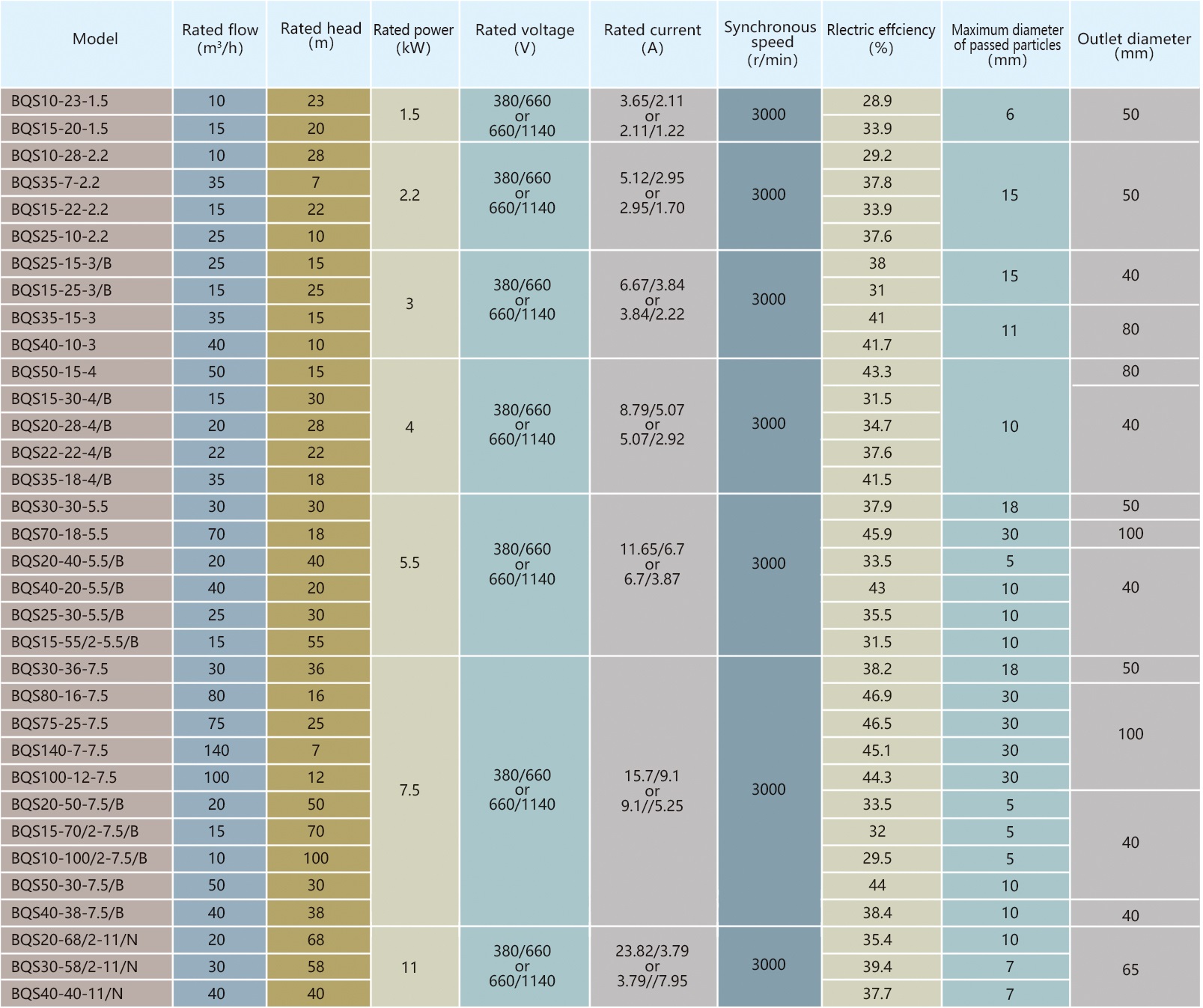

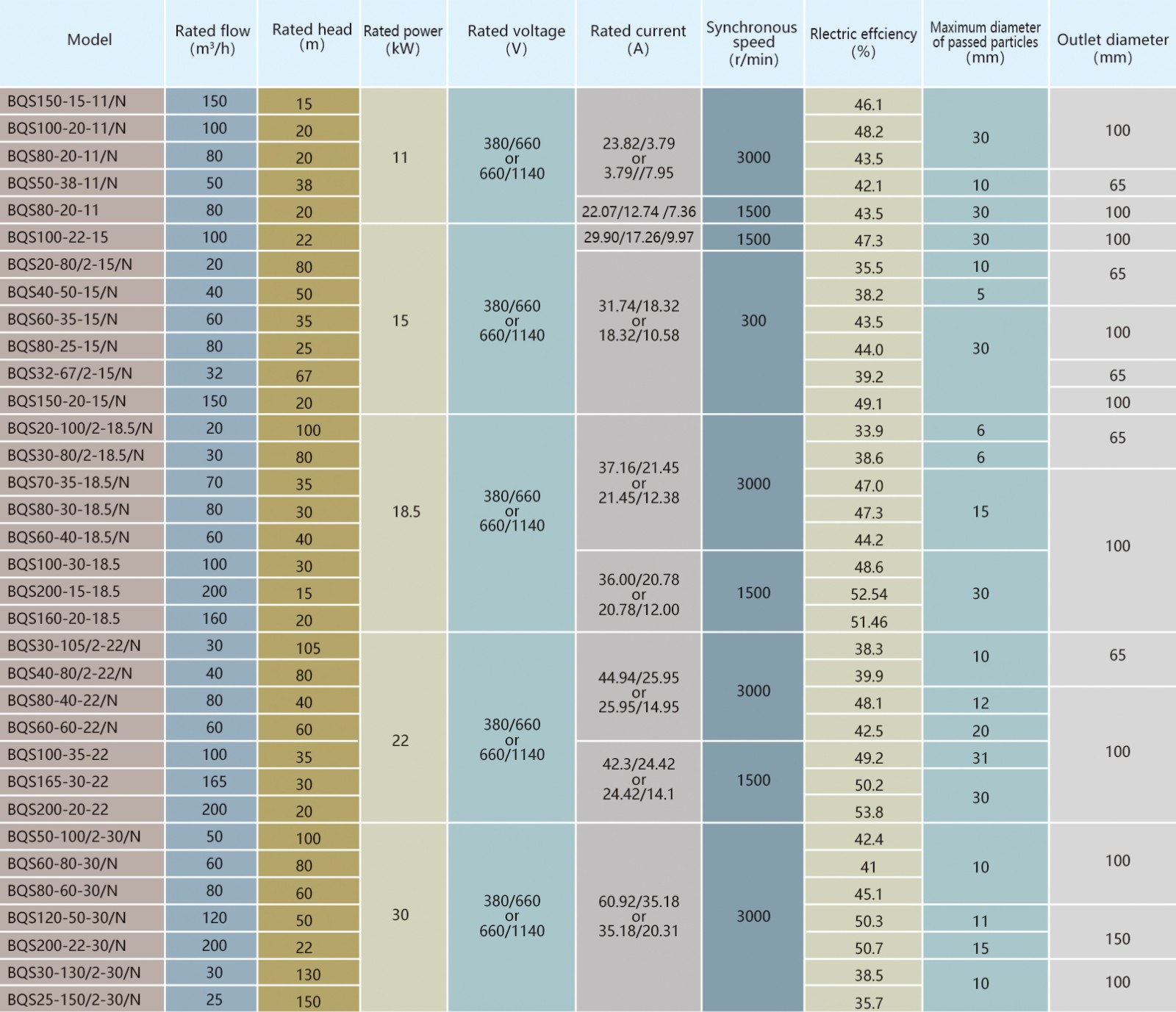

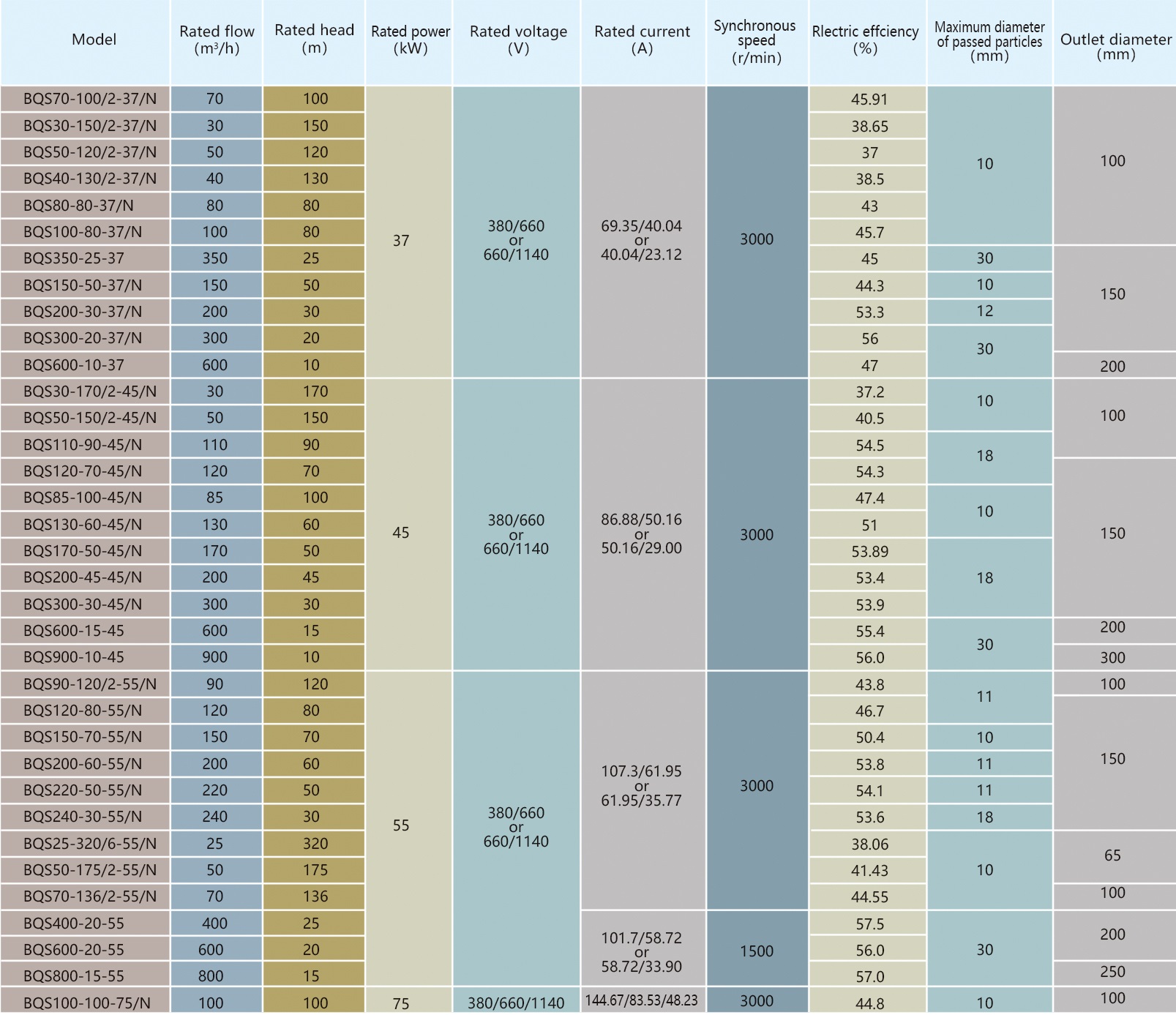

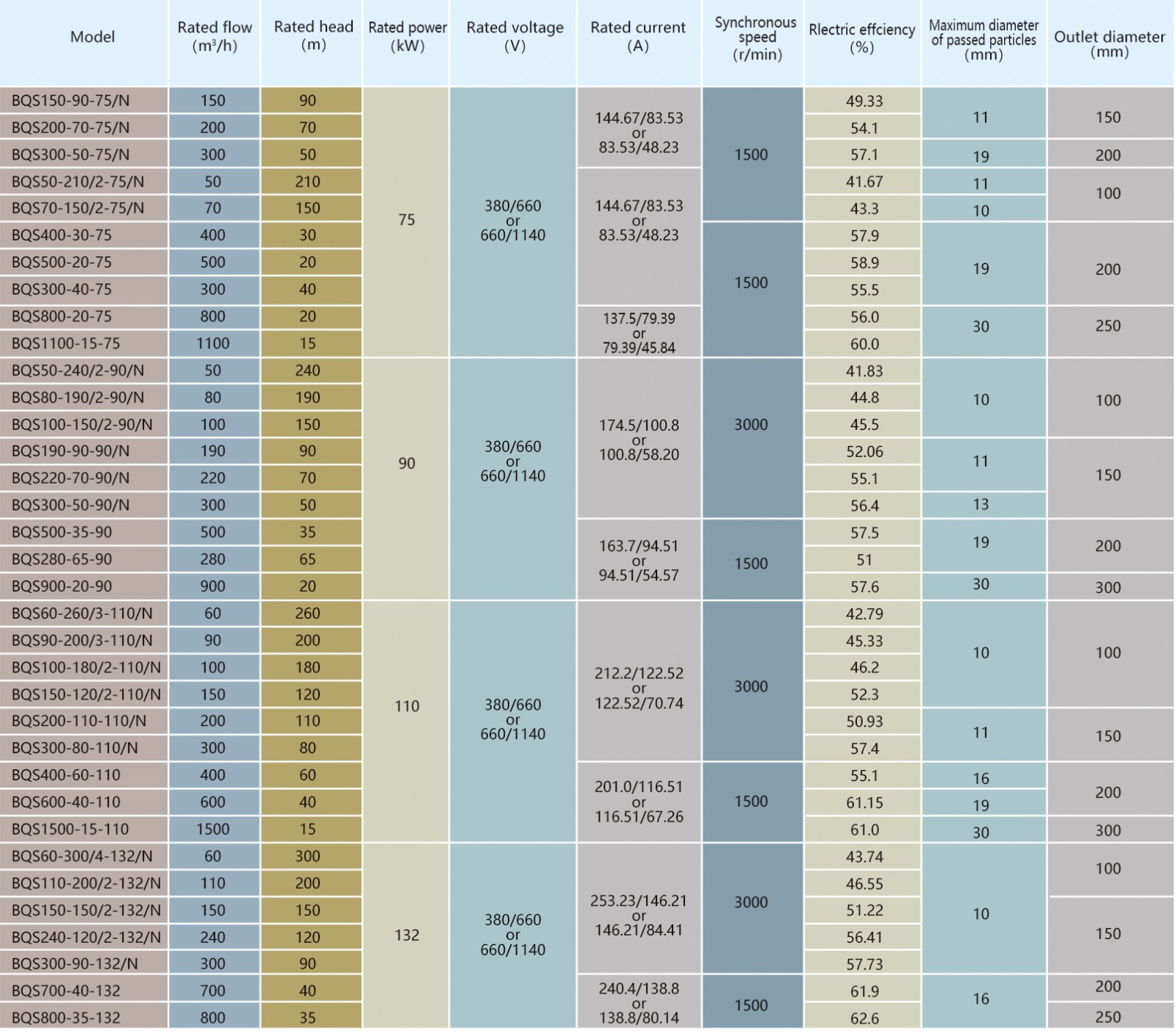

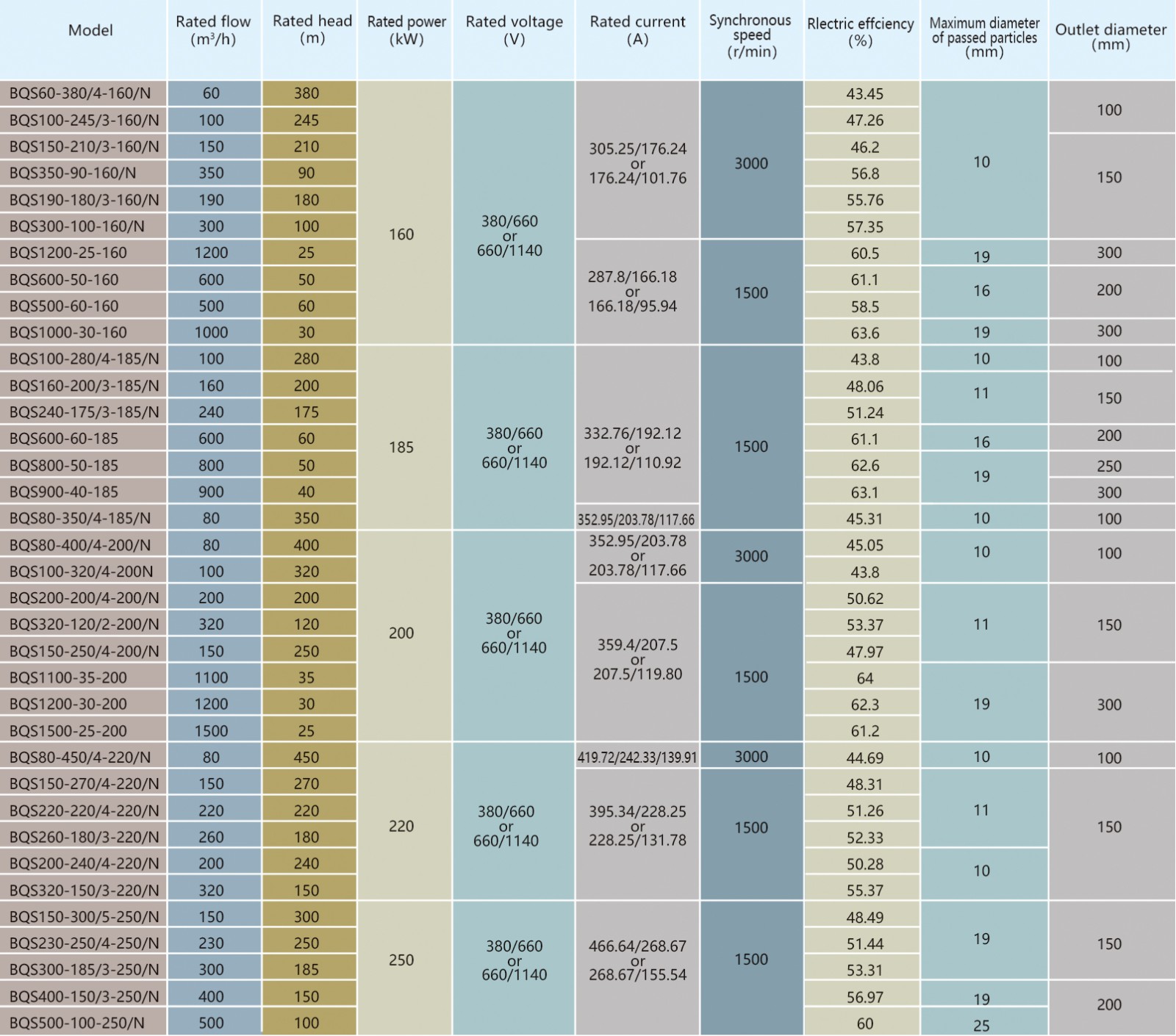

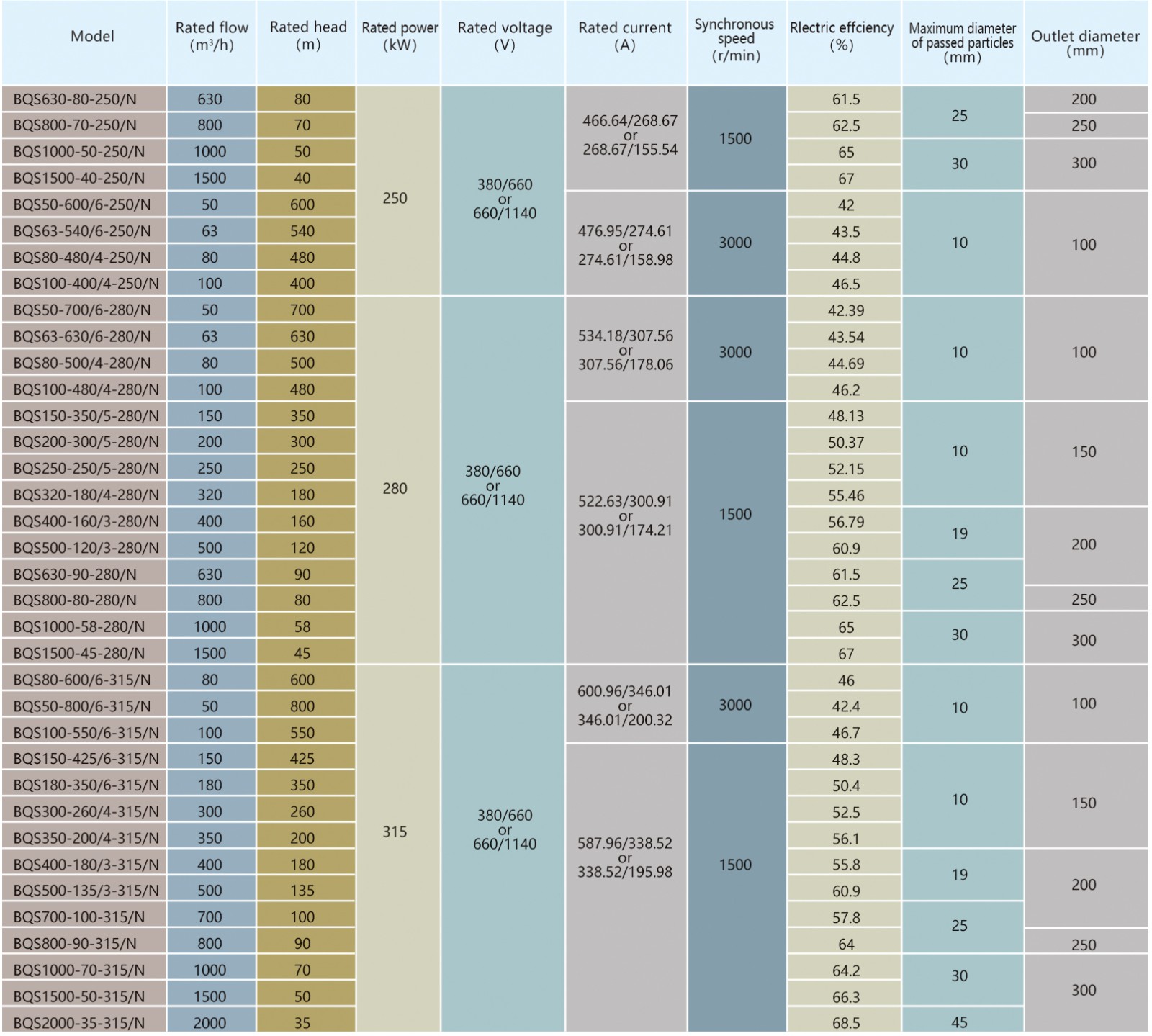

Technical parameters

|  | BQS series-external mounted type The externally mounted electric pump is characterized by a water outlet positioned at the bottom of the pump, allowing direct discharge from the pump body. Typically, this type of pump is designed for applications where the power does not exceed 22kw, making it a small-scale, single-stage, single-suction pump. Its key attributes include a simple yet robust structure, portability, and high discharge capacity. This pump is well-suited for use in environments where water may contain coal slurry, gravel, or other impurities. |

|  | BQS series-built-in type The integrated electric pump features a vertical, downward-type structure with a built-in motor design. The motor housing incorporates an interlayer that serves a crucial role. During water drainage, the liquid flows from the interlayer and exits from the top, providing effective cooling for the motor. Importantly, even in the absence of water, the interlayer outside the motor continues to contain water, ensuring ongoing motor cooling to prevent overheating and potential damage. This self-cooling mechanism eliminates the need for constant supervision, significantly reducing labor costs. The built-in structure is prevalent in the majority of our single-stage and multi-stage pumps, enhancing overall efficiency and reliability. |

|  | BQS series-Semi built-in electric pump The built-in electric pump features a vertical, downward-type structure with an integrated motor design. The motor housing incorporates an interlayer that serves a dual purpose. During water drainage, the liquid flows through the interlayer, exiting from the top to effectively cool the motor. Importantly, even in the absence of water, the interlayer surrounding the motor retains a supply of water for continuous motor cooling, preventing overheating and potential damage. This self-cooling mechanism eliminates the need for constant supervision, significantly reducing labor costs. The majority of our single-stage and multi-stage pumps are designed with this built-in structure for optimal performance. |

|  | BQS series-agitator type It incorporates an innovative stirrer at the pump's base, effectively discharging challenging materials such as coal slurry and slime, incorporating a double-flow channel design for the impeller and volute casing. The outlet between two impeller blades exceeds 30mm, ensuring robust overflow capacity. The impeller blade curve employs patented technology to prevent power input from exceeding motor power, preventing overload under any condition. This multipurpose pump offers users great convenience and can save over 10% of electrical energy. To ensure operational flexibility, the pump features a robust cooling interlayer structure, enabling it to operate both with and without water. This series stands out with advanced technology, superior performance, energy efficiency, and an extended operational life. |

|  | BQS series-stainless steel electric pump The BQS mining explosion-proof sewage desilting submersible pump, meticulously crafted by our company, is uniquely tailored for pumping corrosive fluids containing sand. Engineered with a robust stainless steel construction, the volute casing, impeller, and other flow passage components employ wear-resistant and corrosion-resistant casted alloy materials with precision. The pump base and shell are constructed from high-quality 304 SS, 316 SS and 316L SS etc., significantly enhancing the product's service life. This design ensures durability and longevity, specifically addressing the demands of mine drainage applications. |

|  | BQS110~315KW large power mining explosion-proof submersible drainage pump 1. The pump features a built-in motor with a downward structure, ensuring effective motor cooling and facilitating easy installation and maintenance. 2. The motor design is optimized for high efficiency and reliability. 3. An outstanding hydraulic model is employed to achieve high pump efficiency and superior hydraulic performance. 4. The impeller, guide vane, and volute casing parts utilize core technology, ensuring a no-overload design across the entire pump head range. 5. The pump incorporates patented mechanical seal technology, delivering reliable performance and an extended service life. 6. High-chromium wear-resistant materials are utilized in critical components such as the impeller, seal ring, and guide vane to withstand abrasion from mud and sand. 7. The impeller adopts a wide flow channel design, allowing unimpeded passage of solid particles and ensuring optimal performance without blockages. This series of products represents an optimization and innovation in hydraulic modeling, mechanical structure, mechanical seal, and other aspects. Proven in numerous challenging drainage projects, it boasts high sewage disposal capacity, a large flow volume, and impressive pump head capabilities. |

|  | BQS series amphibious mining explosion-proof submersible drainage pump Safety and antai-explosion, explosive-proof structure, submerged operation, good heat dissipation of motor, no overload throughout whole head design which ensures the safe operation. Motor cannot be burned out because of overload. The pump can be used both submerged in water or on land by connecting suction pipes. According to the use of location, flexible choice of use and one machine multi-purpose. This electric pump can be installed in series to achieve high head drainage. It can adopt submersible installation, land installation, hanging installation, and a variety of tandem installation methods. Electric pump specially designed tandem interface, two or more electric pumps can be installed in tandem. The water conveyed by the front pump is pumped into the rear pump, and the rear pump continues to pressurize to drain the water, to achieve the effect of doubling the head and realizing high head drainage. |

1. Voltage options include 380V/660V and 660V/1140V, three-phase, 50Hz, and can be customized according to specific requirements.

2. The medium density typically does not exceed 40℃, with a pH range of 5 to 9, and a maximum medium weight of ≤11KN/M³.

3. The submerged depth, measured from the impeller center, should not exceed 20 meters.

4. Customized designs are available to accommodate highly corrosive fluids.

5. The diameter of solid contents in the fluid should adhere to the MT/T671-2005 standard. Please specify if a customized design is needed when placing an order.

6. The pump is compatible with MT818.5-1999 coal mines with flame-retardant cable and can be customized accordingly.

PRODUCTOS RELACIONADOS